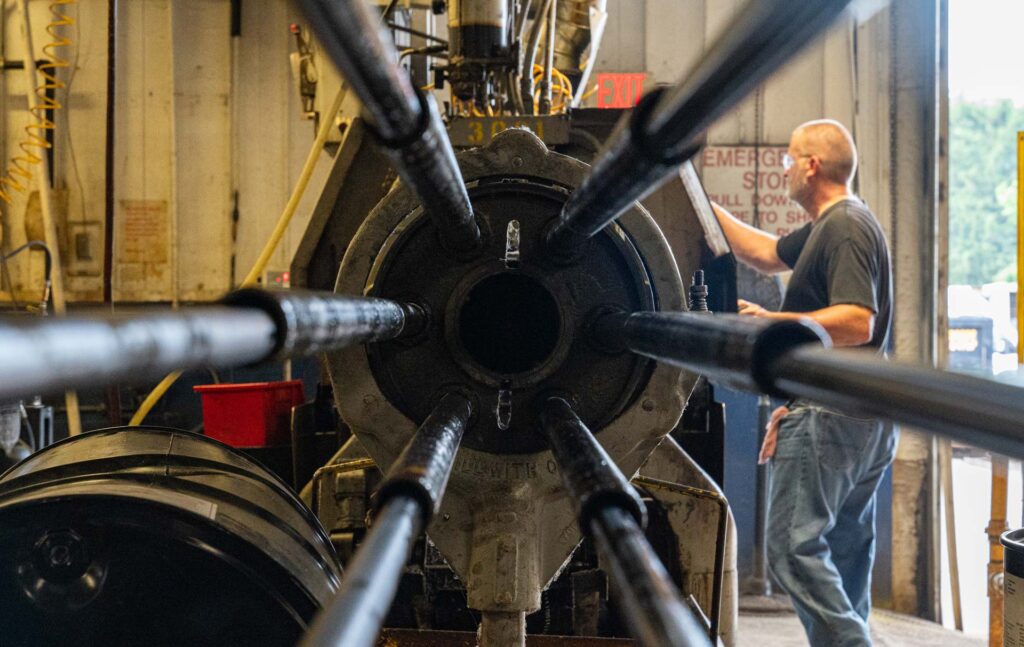

Machining

Part Production

Galion LLC can turn parts as small as .060” ± .0005 and as large as 1.625” ± .0005” in diameter through the utilization of multi-spindle machining processes and/or Swiss CNC machining processes.

Centerless grinding can be done for parts as small as .100” ± .0002 and as large as 2.0” ± .0005.

Materials

Galion LLC has manufacturing experience with both common as well as exotic materials. These materials include:

Equipment List

Multi-spindle capabilities:

CNC Capabilities:

Centerless Grinders:

Presses:

Plating:

Paint:

Other: